| Welcome to Jayhawk Bowling Supply |

|

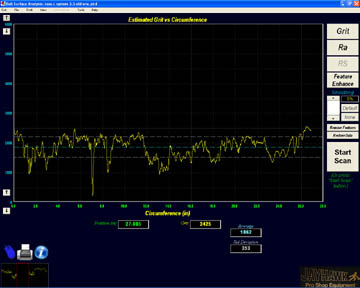

| Jayhawk Ball Surface Scanner Order # 15-7000

Scan A Bowling Ball Surface for Roughness and Consistency Why scan the ball surface?

Easy to use control software allows you to store customer files for later reference and comparison. What Customers are saying about their Jayhawk Ball Surface Scanner's by PAI: Rob Wiltsie RSW Pro Shop Tavares, Florida "Your scanner is the wave of the future in the Pro Shop business. Two years from now if you dont't have a scanner in your Pro Shp, there is no way you can consider yourself an above average Pro Shop operator. I track my sales by categories and my ball resurfacing business is up 35-40% each month over the previous year since I started using the scanner. It is the most valuable tool in my Pro Shop." Don Hogue North Star Pro Shop Fairlawn, Ohio "I thought I could resurface a ball as well as anyone else: but now I know I wasn't even close. With your scanner I know exactly what surface I am putting on the ball and I can show the customer what I am doing in a way they understand. I have a peace of mind knowing that I can match a bowler's surface to his game and I don't have to guess anymore. I guess you could say I don't have to B.S. now. I actually hope no one else around here buys one because it gives me a huge advantage over my competition. My sales are up and business is good." Tom Zernia Lighthouse Pro Shop West Bend, Wisconsin "I am getting new customers from other centers to drive across town to have me scan and resurface their equipment. Bowlers are learning the importance of surface and I am using the scanner in my bowling lessons." Rick Benoit Former PBA Ball Rep and currently a International coach and advisor "I have spent much of my life trying to learn and teach the importance of the invisible aspects of our sport. You can't look at a lane and see how much oil it has, you can't look at a ball and see how much side weight it has and until now you couldn't look at a ball and tell exactly what surface it has. With the scanner, I can work with bowlers and easily teach them the importance surface plays in matching up to the lane." Rusty Bethley Alexandria, LA "At a recent regional tournament held in our center, one of the bowlers said he was not getting the same response out of a high performance bowling ball that he did when it was new. I asked him if any alterations had been made to the cover, and his response was "No, I only had it run through another proshop's resurfacing machine to bring it back to the original surface. Since then, I don't get the back end snap it used to have." I suggested we do a surface scan to see where we were in relation to the original 1500 box finish. The scan revealed a surface texture of 3400 and 2100 in the track area. He insisted my scanner was wrong, because the " resurfacing machine" he used was almost brand new. I offered to run a cycle on my resurfacing machine at 1500 for three minutes to see what we got. He reluctantly agreed, and after the three minutes and a light polish by hand, the surface read 1625 and 1380 in the track area. The next three games he shot 269-300-257, won 17 brackets, two high pots and moved from 8th to 1st. Afterward I got a thank you, a $20 tip, and word of mouth advertising that is priceless. They now think I'm a genius." For ordering information or if you have any questions, please check out our Contact page. We look forward to the opportunity to serve you. |

|

| Jayhawk Bowling Supply and Equipment, Inc. 355 North Iowa Street Lawrence, KS 66044 (785) 842-3237 |